“The way to get to profitability is through efficiency [and] the way to be efficient is to be automated”

Looking in from the outside, it seemed like Bud’s Goods & Provisions was a complete and polished operation. From the company’s sleek in-house branding to aesthetically exquisite shops in Worcester, Watertown, and Abington, it’s a model business with early name recognition on a crowded landscape.

But even with their retail game on point, according to Bud’s co-founder and CEO Alex Mazin, there was a warehouse-sized hurdle blocking their path to success. Namely, he’d been sitting on a large commercial space in Lakeville for several years. Initially intended as a grow facility with a possible storefront, for a while, Mazin couldn’t raise enough funding to cross the finish line.

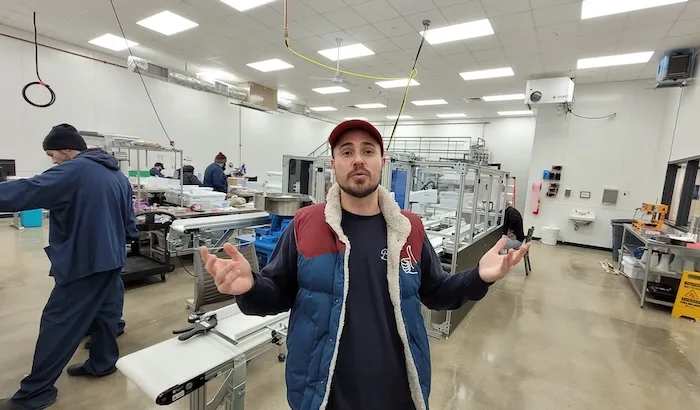

As he stands in the lobby of Bud’s Services, the business that he put in the Lakeville space instead of a greenhouse, he seems relieved to not have built the umpteenth cultivation in the commonwealth.

“We’re focused on servicing packaging needs of [Massachusetts] cultivators and retailers predominantly,” he said. “Half of it is dedicated to the services side of the business, and the other half of it is dedicated to all of the supply chain management side of packaging—boxes, tubes, pouches, labels, jars.”

Mazin continued, “The project has been almost three years in the making, from learning that there is a problem in the packaging part of cannabis to understanding what it would take to solve that problem and building the infrastructure.”

The process involved a lot of observation and countless conversations with industry stakeholders. Mazin recalled, “I would walk into grows and I would see them employing dozens and dozens of people taking joints and putting them into tubes and I thought to myself, That can’t be the best way to do this.”

From there, Bud’s “built a team of engineers and contracted them and designed this pick-and-pack system that can pick up a joint, put it in a tube, and then cap it.”

There’s also a multi-tiered two-story pouching machine that packers fill with cannabis from scaffolding above. Mazin explained, “There’s a vibrational feeder on top which feeds it to the scale. The top buckets will take random weight measures and drop them into the second tier of buckets and then those buckets will talk to each other and drop the perfect weight” into Mylar bags, which are opened using suction cups and vacuums.

“We’re more packaging focused than cannabis focused—all of our equipment is non-cannabis equipment,” Mazin said, showing us their state-of-the-art joint stuffer. It was developed by an Italian engineering firm that’s famous for streamlining teabag production decades ago. “To do that perfect Dutch crown [on a joint], how much paper is left over on the top to fold inward matters down to the millimeter and the formulation to get it perfectly right.”

In setting up Bud’s Services, their team focused on just the stuff they could get perfectly right—preroll production, flower packaging, and labeling.

“Where we are in our industry and the way people think about packaging, my analogy is [potato] chips,” Mazin said. “Most chips are bagged today, that’s the standard practice. Yes, there’s Pringles, there’s the anomalies, but most chips are in bags. And where we are in our industry is similar—but we’re still debating whether it’s more efficient to go in a pouch or a jar.”

For Mazin, there’s no question—the future will come in a pouch.

“If it’s automatable, then it’s scalable,” he said. “And a lot of the packaging in today’s cannabis industry is not automated.”

“Most consumers don’t realize that this industry is not profitable. … A lot of operators are really hurting financially and so they’re all thinking about how [to] save money.”

Mazin continued, “Every kind of company needs to get to profitability. The way to get to profitability is through efficiency. The way to be efficient is to be automated. … It could take years and years for a company to embark upon and really become automated—or they could partner with us.”