We’re saying, Hey, I care about the genetics and I care about how it’s cultivated and I care about the aftercare …

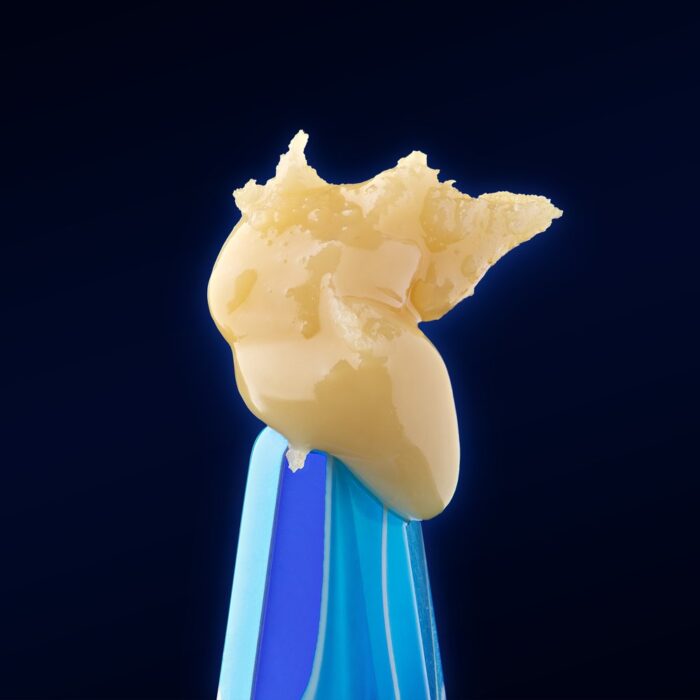

Well known for their exotic extractions, collaborations with the likes of Cookies, and inventive products like their Rosin Popping Boba, Blue River Terps, which opened its first brick-and-mortar in Cambridge last week, is especially recognized in the cannabis community for its proprietary mechanically “deconstructed” solventless dabs. And Tony Verzura, in addition to being COO, is the Edison behind their powerful inventions like Blue River Flan, an outrageously loud rosin that connoisseurs drool over.

I asked Verzura about what goes into the Blue River process and what comes out on the other end, and he brought me to science class detailing all the magic in the middle …

On philosophy …

We’re looking at [cannabis] flower and saying, Hey, I care about the genetics and I care about how it’s cultivated and I care about the aftercare and how it’s cured and how it’s trimmed. It’s the same thing with extracts [as it is with] other products—if we started with trim, or if we started with mids or cured material, these are not the top tier of starting materials.

We make products that are coming from those top tiers of the plant—they’re cut down and then flash frozen. Just the starting input is very important, that makes the biggest difference.

On sourcing …

Our group really tries to focus on who has the best flower in the state, and we also have our own in-house supply chain. We’re trying to set a standard for what we’re smoking and what we’re putting into our body.

On methodology …

Everything is ice water extraction mechanical. Most people know that [Blue River] uses solventless and rosin but it’s important to understand that we can also make different types of innovative delivery methods through edibles.

We do a popping boba that is made without tapioca and can be used as a dessert topping or in a beverage, so it’s a healthy encapsulated juice that has nanotech. So a little bit about the science is that if you take live rosin, it’s not just THC like a distillate—it’s all of the nuances in all of the terpenes. We have to be able to suspend those molecules inside of water, and we do that with crazy amounts of sound and energy. You also have to do that without overheating, so you don’t kill the nuances in all the flavors—that turns it into a really high-tech type of product.

On ingredients …

We also do capsules. It’s really hard to find sugar-free, gluten-free, vegan, calorie-free, soy-free, and dairy-free products in the market, and that’s what we have—they are capsules that are powderized like old-school pixie sticks. You break them open, put it to your mouth, or put it into water where you can bake with them. Or you can swallow them, so they’re multi-delivery.

Most of the general industry is selling distillate with additive flavors or CO2 distillate, RSO, or ethanol products, and in that process it’s a solvent extraction that removes everything from the plant. And then they’re using boiling and distillation techniques, but while you’re doing that you’re also heating up the product, which allows those scientists to isolate cannabinoids, so it’s isolating the singularity of THC, not the spectrum. With nanotech it’s advanced, because they’re able to dial in that particular code for THC.

On technique …

Part of what we’re doing is we’re taking buds, we’re using ice water hand agitation, and the resin heads can sink in water and we can collect them and use technology to rapidly freeze dry around those heads; then we classify the resin heads at the surface level of the plant. So not only do we just collect all of them, we’re going to take it another step and we say, let’s just take the best of the best of those heads.

If you went to a lemon tree and shook the lemon tree and all the lemons fell, you as a consumer may not want to buy all of those lemons, so someone picks the best ones and puts a sticker on them. Once we sticker those resin heads, we then make our baseline premium live rosin products because they’re from live material. Then we take that a step further to what we call AMST—advanced mechanical separation techniques—to make them designer dabs and designer vapes. That’s how we can get better product.